Innovation & efficiency through structural simulation

Reach your targets for gains in mass, quality and time thanks to adapted tools & methods

our mission

Tools & Methods for your Needs

SIMU-FEA puts 20 years of experience in simulating the behavior of reinforced metal/composite/plastic structures at the service of innovative projects aimed at helping companies optimize the mass and mechanical performance of their products, develop methods adapted to modern manufacturing processes and gain efficiency to reduce development time and costs.

Key Points

20 years of passion, curiosity for innovative technologies and the search for ever greater efficiency in the execution of design chains.

20 years of international structural behavior simulation applied to the automotive, aeronautics and electronics industries.

15 years of numerical project management from structural design to the development of advanced numerical methods from the identification of the need to the deployment including the creation and execution of trainings.

5 years of experience in the simulation of structures applied to composites and reinforced plastics from the microscopic scale up to applications on complex assemblies.

Mastering the behaviour of metallic, composite and reinforced plastic materials

The control of the parameters guaranteeing a dimensioning process through predictive calculation, robust and easily applicable on a daily basis.

The flexibility and neutrality of an independent expert to guarantee the choice of the best tools on the market according to your specific needs

Our Goals for your Technology

Lighter, better performing and differentiating products

Faster, more robust and easy to implement calculation methods and solutions

Minimizing the need for prototyping and physical testing

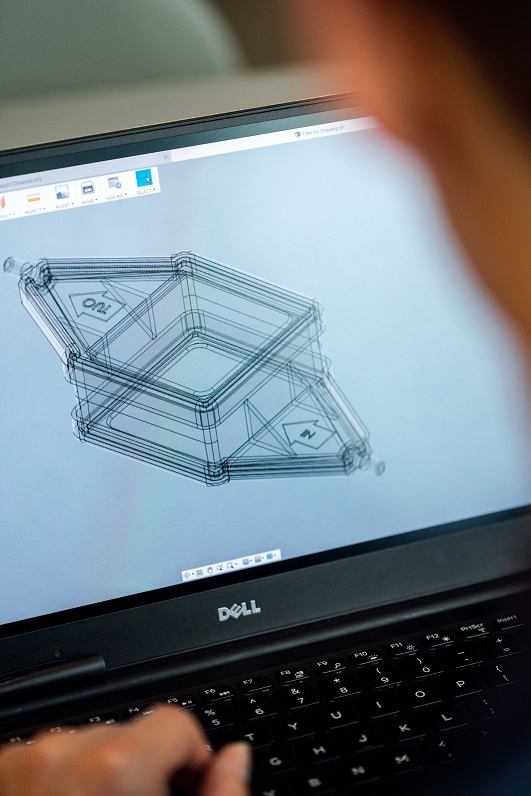

Solver & Software

FEA Code : Ansys

Our services

Design for all Performances

Simulation on single component or assembly (screwed, welded, glued, …)

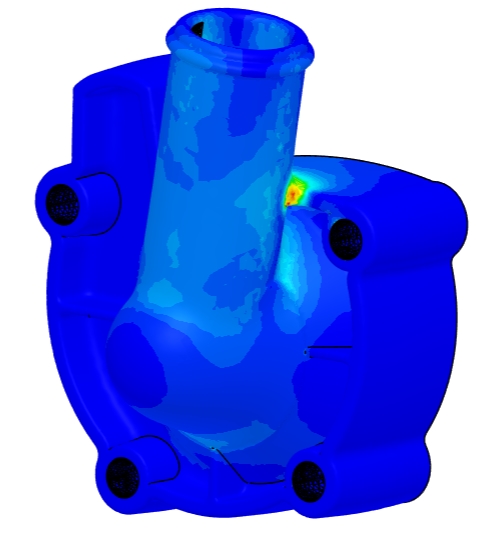

Prediction of stiffness, failure under static, dynamic and fatigue stress.

Prediction of vibration behavior

Behavior of metals, unreinforced plastics,…

Advanced behavior of composites and reinforced plastics,…

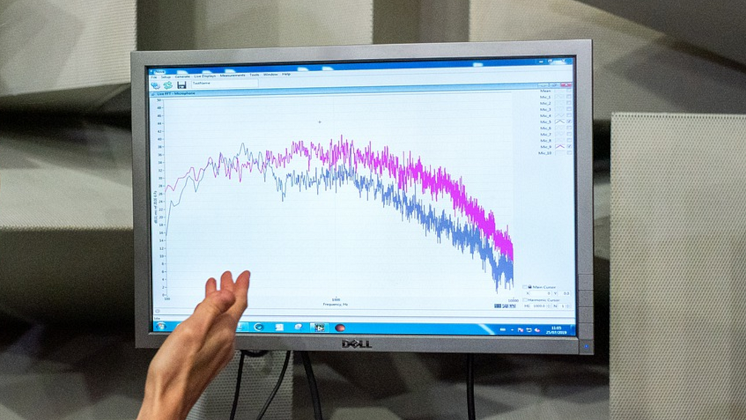

Test / Simulation Correlation

Developing/validating the setup of a calculation

Developing/validating a new method for modeling an assembly,…

Detect the causes of a deformation or breakage observed during the test

Characterize material behavior in terms of stiffness, fracture with or without temperature and strain rate dependency.

Advanced Methods, Trainings & Automation

Influence of manufacturing processes (stamping, molding/overmolding, injected or compressed reinforced plastics, manufacturing additive, lattice structure)

Replacement of metal by plastic

Virtual Material Testing Laboratory (micro/macro scale)

Automated geometric optimization

Creation of automated workflows

Creation of “domain specific” modeling standards

Integration of Standards in dimensioning

Training on methods and tools

industries

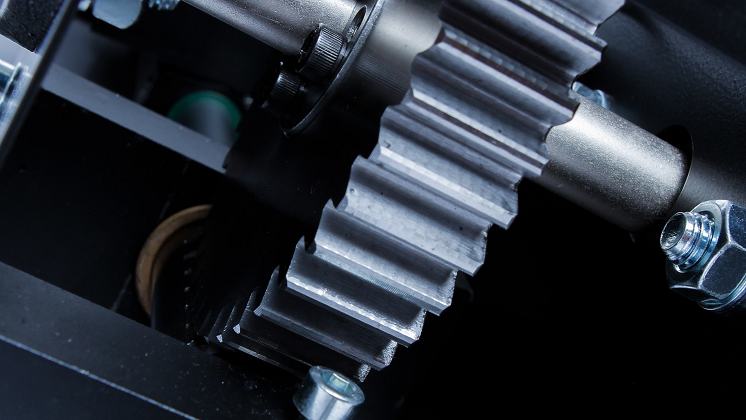

AUTOMOTIVE

AEROSPACE

Heavy Industries

Goods & Electronics

materials

Metals & other homogeneous materials

continuous fiber composites

injected or compressed reinforced plastics

3D Printing & lattice structures

performances

static

dynamic

fatigue

impact

why choose us ?

Satisfaction Guarantee

Smooth communication, high expertise & project management

Innovating tools

We use the latest developments in calculation tools and methods to guarantee optimal results.

Confidentiality

The confidentiality of our customers’ information is essential to ensure the quality of our services.

Call us +33 3 39 03 42 42